Thorsten Helbig

Associate Professor Adjunct

Thorsten Helbig is founding partner of Knippers Helbig (KH), an award winning structural and façade engineering firm based in Stuttgart, New York and Berlin, established in 2001. At KH, Helbig established an open-minded approach towards engineering design and developed new forms of collaborations with clients, architects and industry partners. KH works with an extensive range of materials and explores the inherent potential of new fabrication technologies: from robotically fabricated canopies made of woven carbon fiber reinforced polymers, textile-reinforced concrete structures, fiber reinforced ceramics to buildings utilizing mass timber strategies. Helbig’s engineering approach strives to interweave conceptual design with the professional experience of executing technically complex projects with a focus on the application of progressive materials and state-of-the-art design and construction technologies.

Thorsten gained vast experience as an engineering partner for renowned architects such as Renzo Piano Building Workshop, Diller Scofidio + Renfro, Gehry Partners, Stefan Behnisch, and Grimshaw among others. As Partner-in-charge, Helbig has led numerous award winning projects in competition and execution such as T3 Bao’an Int’l Airport, Shenzhen, China with M. Fuksas, one of the first large scale projects using parametric design tools for geometrical and structural optimization. Currently he is the key designer of a series of what will be the first of its’ kind: Robust, Integral Timber Footbridges, which received the notable German award for Timber Constructions in 2017 for the concept which was developed in a research project. His projects were awarded the German Steel Construction Award, Material prize, Civil engineering Award (Recognition, 2018), Mies van der Rohe Award among others.

Helbig, experienced and educated as a builder, spent several years working on construction sites. He studied civil engineering and architecture at the UAS Bielefeld, Germany, receiving his Degree in civil engineering in 1994. Prior to founding Knippers Helbig in 2001, Thorsten was a structural engineer and project manager at SBP Stuttgart, founded and led by Jörg Schlaich and Rudolf Bergermann.

Thorsten Helbig lectures regularly at conferences and seminars across Europe and the US and is the author of numerous publications. He has been published in a wide range of international architecture and engineering books and journals. He is a member of the Chamber of Engineers in Germany, the International Association of Bridge and Shell Structures (IABSE) and the International Association for Shell and Spatial Structures.

Helbig has participated in and critiqued for several design studios, including University of Pennsylvania and University of California, Los Angeles. He has lectured at educational institutions in Europe and the US such as Harvard Graduate School of Design, TU Delft and TU Vienna among others.

Projects

-

Bao'an International Airport T3, Shenzhen (China)

-

State Opera House, Berlin (Germany)

-

Peek & Cloppenburg Flagship Store, Cologne

-

Trumpf Smart Factory, Chicago / USA

Back

Bao'an International Airport T3, Shenzhen (China)

Shenzhen International Airport is located in the south east of China with a capacity of 45m passengers a year. Knippers Helbig was in charge of structural design, facade planning and geometry engineering. The terminal has a length of 1.6km and its gross area of 459,000m2 added 78 gates to the existing airport. The building has a 300.000m2 double-layered facade and roof construction with spans up to 80m. Due to the free form design and varying dimensions of the façade panels a parametric development of the geometry was necessary. To manage 60.000 panels attached to a free form and based of different window sizes Knippers Helbig developed parametric design tools and custom details.

The structural concept for the concrete substructure was developed in close cooperation with local engineers in order to define a system meeting the architectural image and considers local fabrication standards.

The steel structure consists of 450.000 members and allows for high earthquake loads. Cross bracings are providing high level of stiffness, all other members are following the diagrid in order to achieve a maximum transparency of the facade.

https://www.knippershelbig.com/en/projects/shenzhen-international-airport

Image by Leonardo Finotti

State Opera House, Berlin (Germany)

The reconstruction of the state opera house "Staatsoper Unter den Linden” (1741, Georg Wenzeslaus von Knobelsdorff) included improving the acoustics of the concert hall. First and foreground was the optimisation of the reverberation time. For this purpose the top floor ceiling was lifted by 5.0m. Creating additional space between the upper stands and the ceiling to fit a reverberation gallery comprising reflective and sound absorbing components. To form a visual space partition a mesh of fibre reinforced phosphate ceramics with a dimension of 250 m² has been installed in front of the wall cladding. The mesh size varies according to the parametric geometry formation from approx. 20cm side length to the surface areas without recesses at the upper edge with diameters of 3.5cm. A CNC five-axes robot milled the shapes out of a dense foam. This is followed by casting the ceramic matrix reinforced with glass-fibres. The multiple centre curve geometry allows for a segmental prefabrication of identical components with max. dimensions of 3.5 x 4.0m.

Since material behavior and mechanical properties have not been investigated before extensive testing series and research was necessary and conducted in collaboration with the Institute for Building Structures and Design (ITKE), University Stuttgart.

https://www.knippershelbig.com/en/projects/staatsoper-unter-den-linden

Peek & Cloppenburg Flagship Store, Cologne

The architect Renzo Piano designed a glazed dome for the textile company "Peek & Cloppenburg“. It features a skin consisting of 6,800 individual overlapping glass panes.

The five-storey department store in the inner-city Cologne is entirely wrapped into the free-formed facade shell. The vertically arranged trusses of wood slats and the horizontally running facade tubes are linked to the shell structure by diagonally stretching cables. The number of wood slats are graded from floor to floor according to the strain. The trusses of wood slats made of Siberian larch were completely prefabricated. Supporting the shell structure on just a few rigid positions of the carcass enables an almost complete isolation from distortion forces. On the forth floor the façade shell is attached by consoles. In order to maintain the impressive effect of the facade also inside, the ceilings do not touch the glass skin.

https://www.knippershelbig.com/en/projects/flagshipstore-peek-cloppenburg

Image by Marcus Ebener

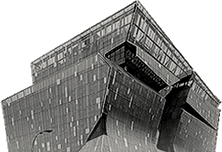

Trumpf Smart Factory, Chicago / USA

The new Trumpf showroom located in Chicago showcases machines used for sheet metal processing. Accordingly, both structure and façade of the building demonstrate, in an exemplary way, the wide spectrum of possibilities for the utilization of steel.

The main hall’s roof structure consists of Vierendeel trusses, which rest upon thin stilts. The trusses consist of laser cut metal sheets and support the roof as well as a ‘skywalk’ spanning the production hall offering visitors a bird’s-eye-view of the machines.

The façade is formed of vertical double-T-beams made from Corten steel positioned on the building’s exterior. Thermally insulated spacer elements ensure a firm connection between the steel beams and the aluminum curtain wall façade. The slim appearance of the façade was achieved by transferring the wind loads to the primary steel construction.

The same applies to the minimized detailing of the parapets as well as all connections, which could be developed discretely, thus focusing on the essential, defining aspects of the building.

https://www.knippershelbig.com/en/projects/tusc-trumpf-showroom-chicago