Chapter 1: Extraction

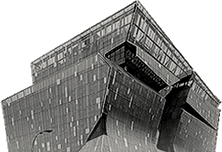

The process of hydro-fracking begins at the well pad with the drilling of a vertical well. After the well has been drilled, a larger drill rig creates the horizontal drilling bore, and drilling mud is used to cool and power the drill. Depending on the chemical content of the drilling mud, drill cuttings can be deemed hazardous waste when combined with this mud. This initial phase can take up to two months.

Once the well is drilled, dried, cased and grouted, fracking begins. After the cement casing is installed, a perforating gun sends down electrical currents that fracture the rock. Fracking fluid, a mixture of water and highly toxic chemical additives, is then injected at high pressure to both maintain and induce fractures in the gas-bearing formation, thereby increasing permeability and facilitating the release of trapped gas. A pressure of up to 15,000 pounds per square inch may be employed during multi-stage fracturing events. This is a pressure range typically associated with bombs and military armaments.

Each well requires between 2-7 million gallons of fracking fluid. To make this fluid, water is obtained from local surface or ground water sources. To date, most fracking operations have used on-site fresh or low salinity water.

Approximately 10 to 50% of the fracking fluid returns to the surface during the drilling process as flowback water, which is estimated to contain between 9%-35% of the initial fracking chemicals injected. Flowback water contains high levels of total dissolved solids (TDS or salts), metals and naturally occurring radioactive material (NORM) from the drilling process, which is stored in open lagoons.

Flowback generates the largest amount of waste from the gas wells. It can be reused to fracture additional wells, injected into underground disposal wells, treated or stored in open lagoons for dilution and reuse. Open lagoons are prone to liner failure, evaporative spread of volatile chemicals and direct human and animal contact.

The hydro-fracking process takes approximately 4 months to complete from preparation to waste disposal.

Following fracking, the drilling rigs are removed and natural gas extraction begins. During this process, gas is collected at the producing well and piped or transported via truck to a processing facility.

Wastewater pumped from a well with natural gas is known as production brine. Due to the Marcellus Shale’s marine origin, the production brine contains high levels of total dissolved solids (TDS or salts), metals and naturally occurring radioactive material (NORM). Production brine can be 5 times saltier than seawater.

Between 300-6300 gallons of production brine can be generated per day. Production brine requires secure on-site storage in steel tanks and a hazardous wastewater disposal plan.

The radioactivity of production brine waste from traditional vertical wells drilled into Marcellus Shale was found to be 267 times the recommended EPA levels under the Safe Drinking Water Act. Protected under the 2005 “Halliburton loophole,” which prevents the U.S. EPA from regulating the natural gas drilling industry, the oil and gas industry is exempt from federal laws dictating the handling of toxic waste, thereby leaving the responsibility to individual states.